After spending a gap semester with the Star Wars team at Hasbro, I knew that it was time to complete the ritual that every young Padawan must undergo: forging their own lightsaber. With the help of the resources at Yale's Center for Engineering Innovation and Design, I was able to design and fabricate my own 3D printed electronic lightsaber.

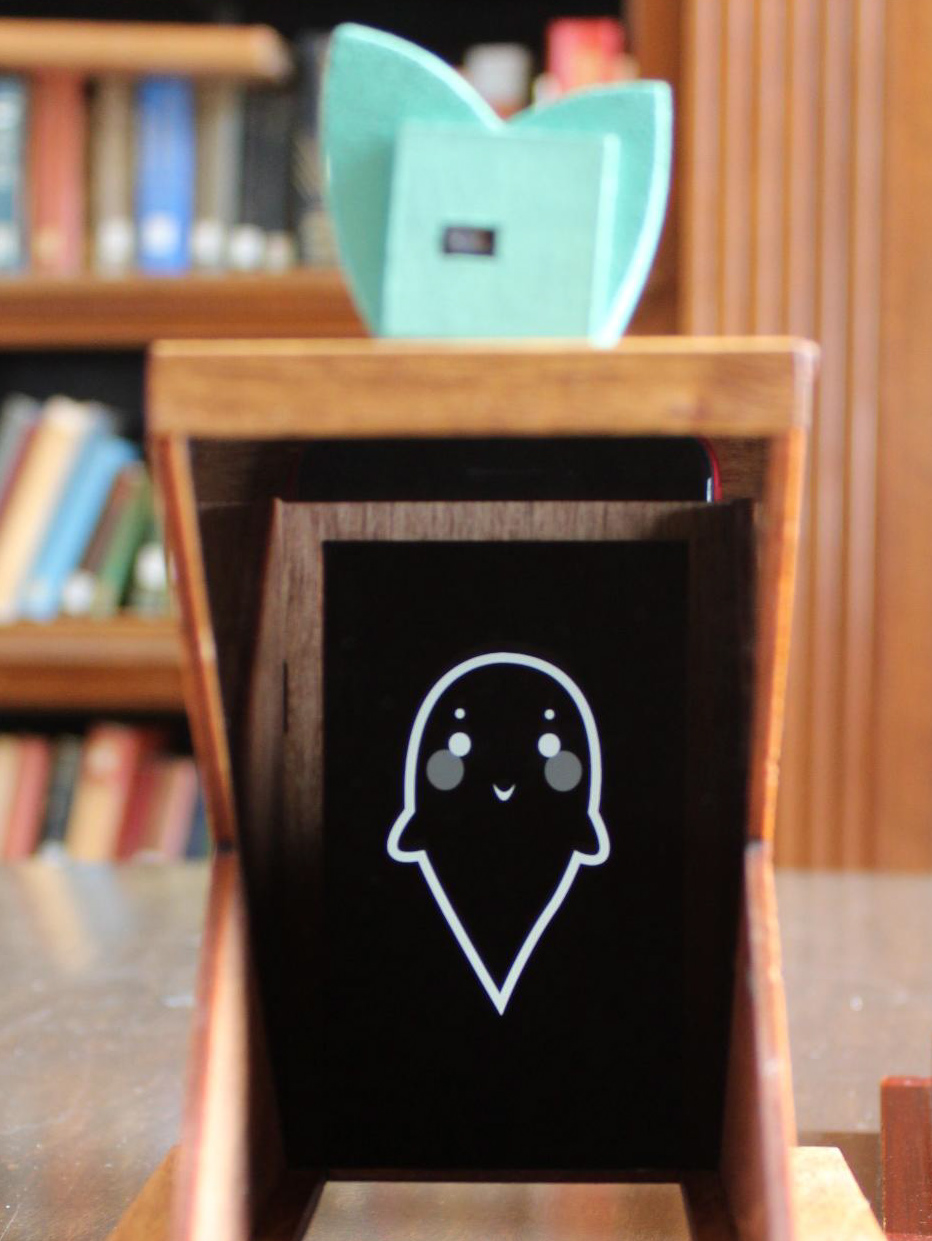

The lightsaber features three 3D printed elements. The first is the internal chassis, the removeable housing for all of the electronics. This was first modeled on SolidWorks, then printed on the Stratasys F370. The dissolvable supports made it easy to design multiple negative spaces and overhangs without breaking the print into separate parts. The second element is the hilt, which was printed in grey resin on the Formlabs 3L. I took heavy inspiration from Obi Wan Kenobi's lightsaber when creating the design. It features a screw-on pommel, allowing for easy access to the chassis. Lastly, the blade tip was printed in clear resin on the Formlabs 3L.

The electronics consist of several components: speaker, battery, push button, Tri-Cree LEDs, and Verso soundboard (or the "brain"). I fitted each component precisely into the chassis, then wired and soldered everything to the soundboard.

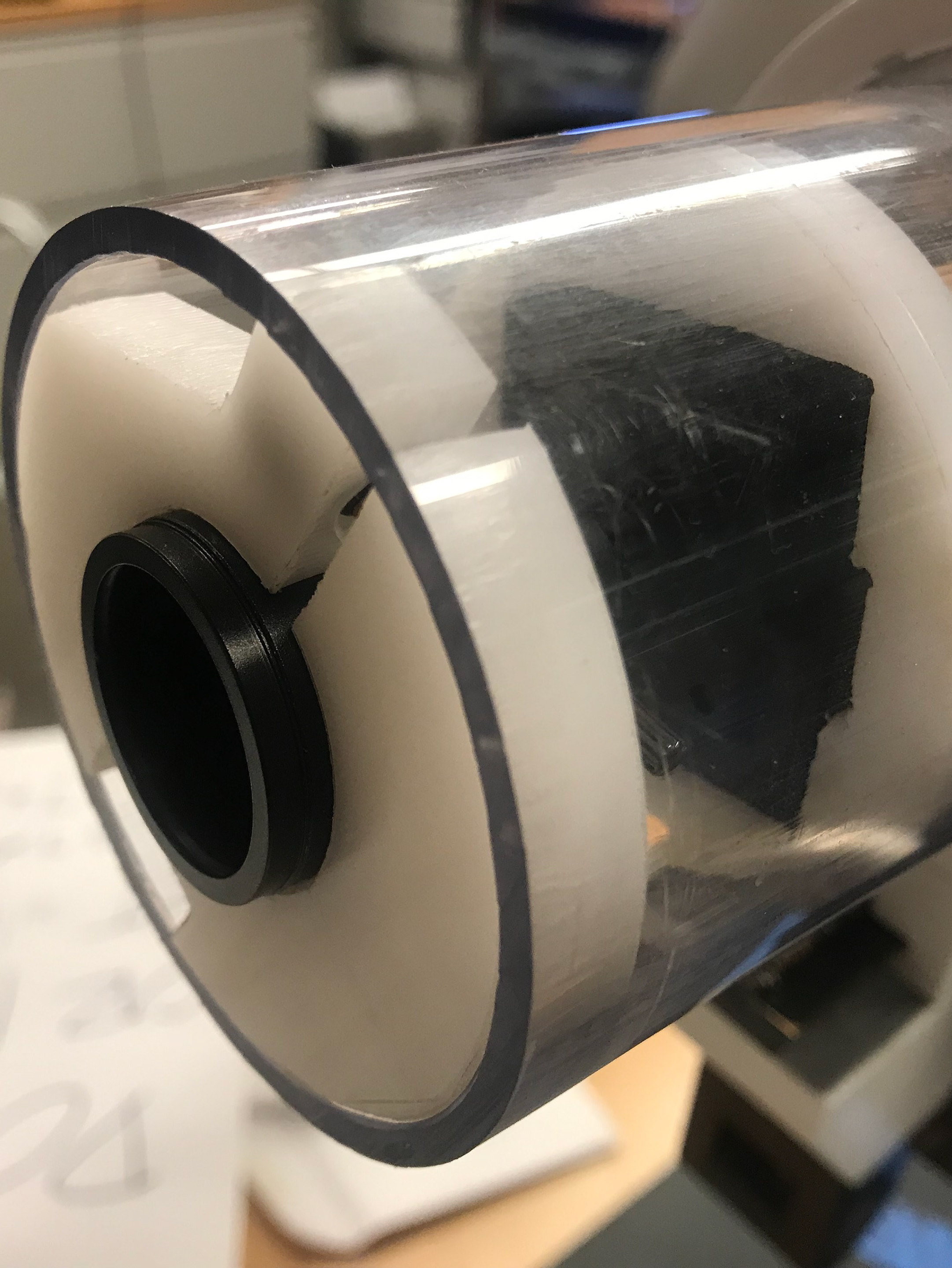

The blade is quite simple, as the light comes from a single source at the base. It is made of a clear polycarbonate tube that has been lined with cellophane to diffuse the light emitted by the LEDs. The tip of the blade is topped with a 3D printed cap, completing the rounded appearance of the blade. It is held in place at the hilt with a single set screw.

Left: 3D model of the hilt on SolidWorks, Right: 3D model of the electronics chassis on SolidWorks